High Efficiency Separator

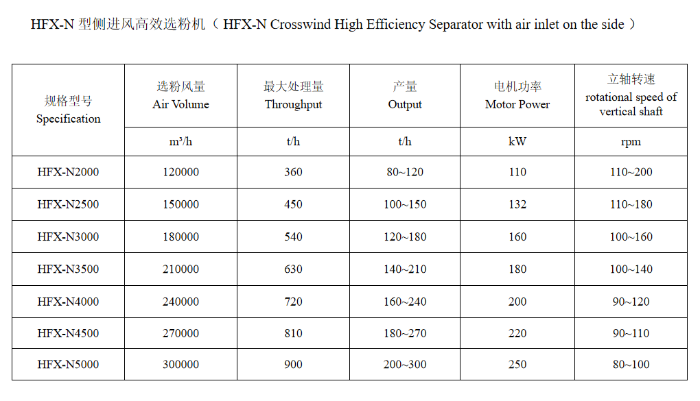

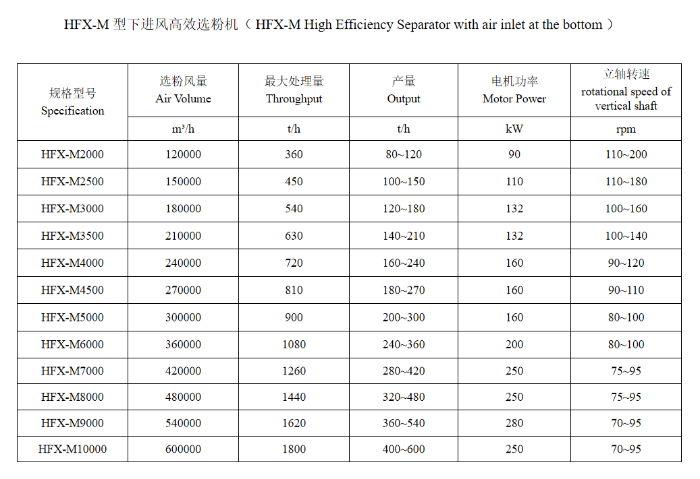

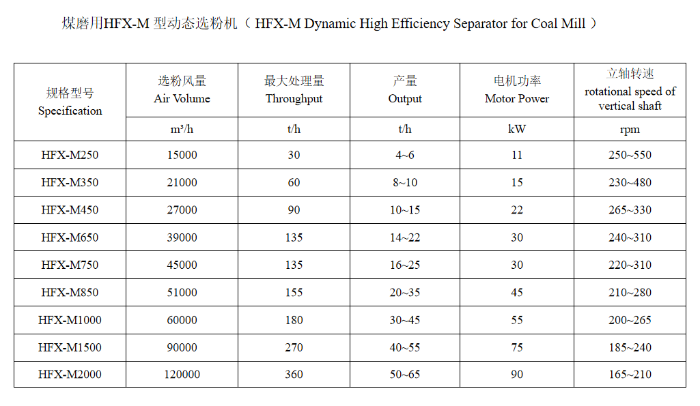

Hefei Cement Research & Design Institute established separation technology research team in 1959. It firstly developed the 3rd generation of high efficiency separator domestically, firstly applied high efficiency separator in raw mill and coal mill system, and firstly together with roller press made up combined grinding, raw meal final grinding, cement semi-final grinding system and so on. It was awarded “New Product at the State Level”, “Excellent Energy Saving Fruit at the State Level”, “Famous-brand Product in Building Material Industry” and “the Second Prize of Scientific and Technological Advancement in Building Material Industry”, etc. Recently, it won five innovation patents, and more than 20 utility model patents. Dozens of thesis have been published on the national first grade periodical about our famous brands of DS and HES high efficiency separators, and HFVW horizontal dynamic separator. Recently, we have developed HFX series high efficiency separator, which combines advantages of various types of separators and whose separation efficiency is more than 10 percentage points higher than other high efficiency separators. 3~30μm granule content and strength of cement are increased. 200μm sieve of raw meal is reduced to increase burnability of raw meal; 80μm sieve of pulverized coal is reduced to satisfy the burning requirement of low quality coal. Different types of separator are selected to meet the separation of various grain sizes from 50 meshes to 1250 meshes, according to differentiated demand.